Network

Video Solution

Network

Video Solution

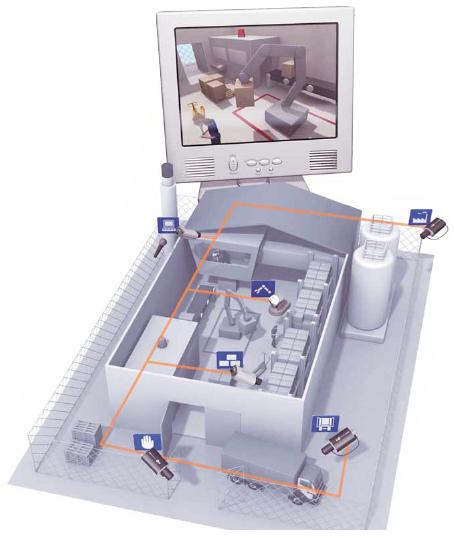

Market Segments - Industrial

Network

video is currently being used for monitoring manufacturing lines,

industrial and pharmaceutical processes, automation, warehouse

and stock control systems to name just a few examples of industrial

applications. Efficiency at a production plant can be greatly

enhanced through the use of "virtual eyes".

The

diagram illustrates the ways in which camera can be used in an

industrial setting.

Control

Room

At, for example, a rock crushing plant or chemical processing

plant, where there are health hazards for employees, remote monitoring

of production processes provide the ideal solution. A network

video system feeding images to the control room gives a plant

worker the opportunity to check for machine malfunctions without

the slightest risk of inhaling dust or toxic fumes.

Production

Line or Robots

Cameras observing an automated production line or factory robots

can be programmed to send e-mail alerts if something unusual occurs.

That way, the plant's staff is relieved of the monotonous and

time-consuming process of watching out for machine malfunctions.

Trouble

Shooting

If a malfunction does occur and there are no service engineers

in the area, network video can be used to set up a virtual meeting

and get technical support at a distance.

Goods Entrances

The accumulated costs of petty theft of raw materials entering

and manufactured goods leaving a plant can add up to a huge problem

over time. Network cameras work as a crime deterrent here, as

well as offering an easy way to check the efficiency of the loading/unloading

methods being used.

Storage

Areas

Making sure a storage system works well, that goods can be accessed

and are efficiently managed, can significantly affect the bottom

line at a manufacturing plant. The fact that storage is often

handled at remote sites, usually due to the lower cost, makes

this another good place to install network video.